Wood is the most common home building material in the U.S., where about 90 percent of all homes are built with wood frames. Most of that wood comes from land classified as ‘timberland’, sometimes referred to as tree farms. These are lands on which rapid-growing softwood trees such as pine, fir and spruce are grown and cut down on a rotating basis known as a cutting cycle. Trees used for lumber are cut when their growth rate slows down, usually in less than 50 years. Each of these trees can yield about 260 board feet of wood (a board foot is 1 foot square by 1 inch thick).

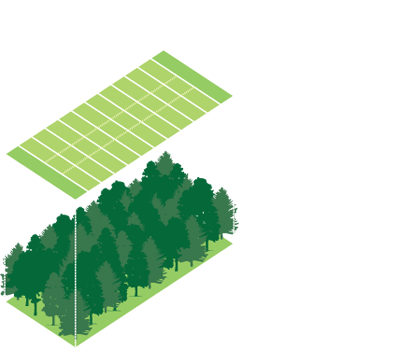

A 2,700 square-foot house requires approximately 18,000 board feet for its frame. It takes about 70 trees to provide that much wood. An additional 15,000-16,000 square feet of other wood products are also needed, such as plywood or oriented-strand board, veneer, particle board and fiber board. On average, it takes about one and a third acres of timberland to build a house.

Forestland is essential to a healthy environment. Trees absorb carbon dioxide and produce oxygen, and forests provide stable habitat for wildlife (about 70 percent of all animal species live in forests), control erosion and in numerous other ways are beneficial to the land. Their destruction would cause ecosystems to collapse while air quality would deteriorate.

Although most of the virgin, old growth forests in the contiguous U.S. have by now been cut down, there are over 500 million acres of regrown timberland today, which is about 20 percent of the total area of the country, including Alaska and Hawaii. (Timberland is classified as forestland capable of growing 20 cubic feet of commercial wood per acre per year. Total forestland in the U.S. is between 650 million and 750 million acres, depending on the definition of forest. That’s about a third of the country. Worldwide, forests also cover about a third of all land area.)

According to the U.S. timber industry, logging is now sustainable. Logging has typically involved clearcutting, which is still the prevalent method. To address the negative image of this practice, some logging operations now use less destructive methods. The Sustainable Forestry Initiative, or SFI, is an industry-sponsored certification intended to encourage sustainable logging and forest management practices such as selective logging and tree planting.

Industry critics, although appreciative of these practices compared to previous ones, say that the resulting woodlands are unable to sustain healthy ecosystems, which require centuries-old undisturbed forests with a diversity of plant species.

As with concrete, there are no materials that could easily replace wood as a home construction material in the U.S., so the only immediate solutions, besides improving forestry management practices, are to use and waste less of it—about one-sixth of the wood delivered to a typical construction site ends up in landfill. This can be accomplished with more efficient building practices:

• Framing methods that use less wood, called advanced framing.

• Making boards out of leftover pieces and residue, called engineered lumber.

• Architectural plans based on standard wood sizes. Wood pieces come in standard lengths of multiples of four (i.e., eight-foot, twelve-foot, and sixteen-foot long 2x4s), so also making room dimensions in multiples of four wastes less wood.

During the 1970’s energy crisis, the National Association of Home Builders’ Research Foundation conducted studies to identify what structural configuration was necessary to maintain superior strength and allow the maximum insulation in wall cavities to improve energy efficiency. The result was called “Optimal Value Engineering” (OVE).

The basics of OVE:

• Walls are framed with 2x6s on 24-inch centers (the space between studs) rather than 2x4s on 16-inch centers.

• Corners are made from two studs rather than four.

• Headers (the support above windows and doors) are sized according to the load they actually carry.

• Roofs are built with trusses rather than framed conventionally.

• Floors are framed with I-joists rather than sawn lumber.

• Insulating sheathing replaces conventional plywood or oriented strand board.

• Autoclaved Aerated Concrete (AAC) - takes the place of a number of components used in standard stick-frame—wood, insulation, house wrap, and drywall—all in a single product.

• Engineered Lumber - uses wood fiber more efficiently than solid sawn lumber, and can be made from wood species that regenerate more rapidly.

• Steel studs with Recycled Content - made with recycled materials, they are also dead straight, so walls and ceilings are true.

• SFI Certified Wood - certified by the Forest Steward Council (FSC) and the American Forest and Paper Association, from trees logged using a number of sustainable practices that cause less damage to forests.

More topics:

This project was researched, designed and coded by Phil Loubere and Jordan Kennedy in Middle Tennessee State University’s School of Journalism, Visual Communication concentration.